Many materials make good insulators. But not every insulation type is right for every application. In order to make the best choice for your project, it’s important to understand the different materials available on the market today.

The sea of choices can be narrowed down into two major categories of insulation. Let’s compare: foam board insulation vs fiberglass.

Project Specific Requirements

From fiberglass to foam, you can buy insulation in batts, rolls, or boards. Here are some factors to consider before selecting your building insulation:

Budget

Desired R-Value

Construction Type

Installation Method

Code Requirements

Special Considerations

Below, we’ll cover the differences between foam board insulation vs fiberglass as they relate to these considerations.

Foam Board Insulation Types

Foam board insulation is a lightweight rigid board, usually 4-by-8-foot in dimension. The chemical makeup of these boards varies from polystyrene (EPS or XPS) to polyisocyanurate (polyiso or iso). Foam boards are formed by chemically altering these plastic resins, heating and expanding the material to create air pockets.

Here are some quick comparisons of foam board types:

Extruded Polystyrene (XPS): Unfaced foam boards

Expanded Polystyrene (EPS): Unfaced foam boards

Polyiso (iso): Foam core with facers on both sides

Installation of Foam Board Insulation

Foam board insulation can be installed in a variety of ways, including loose-laid, mechanically fastened with screws and plates, or glued to a substrate with adhesive. Common applications of foam board insulation include: slabs, basement walls, exterior walls, and roofs. The modular dimensions of foam board insulation make it easy to fit these boards together, creating a continuous insulation application.

Fiberglass Insulation Types

Unlike rigid foam boards, fiberglass insulation is flexible and soft. This insulating material is made from spun fiberglass and binders and it comes in loose-fill or rolls or batts that are sized to fit between stud and joist cavities. Fiberglass rolls and batts are available faced with kraft paper or unfaced.

Installation of Fiberglass Insulation

Fiberglass is made to fit inside wall cavities. Paper-faced fiberglass can be stapled to wood framing to hold it in place. Since it is soft and flexible, fiberglass insulation must be secured to and supported by surrounding framing when installed. It loses some of its thermal insulating value when compressed, so it needs to remain fluffy and not in compression. Loose-fill fiberglass insulation requires professional installation and special equipment.

Comparing R-Value Performance

When comparing foam board insulation vs fiberglass, thermal performance is a key factor to evaluate. The thermal performance of insulation is measured in R-value. A higher R-value means that the insulation performs better at reducing heat loss through it. Polyiso has an R-value of R6 per inch, while fiberglass has an R-value of less than R4 per inch.

R-Value of Insulation by Type

Cost Comparison: Foam Board Insulation vs Fiberglass

An adequate comparison of building materials requires a look at three factors:

Material cost

Installation cost

R-value

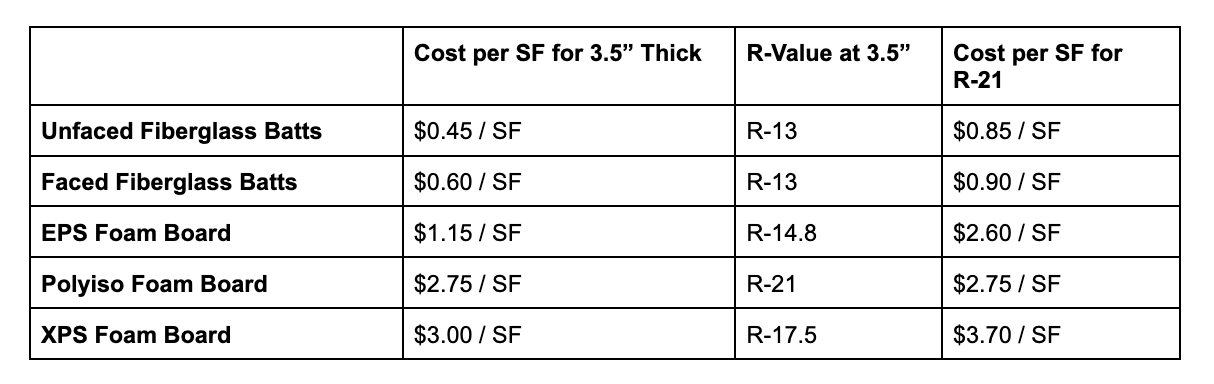

Let’s compare the current price of each type of insulation for 3.5” thickness.

At first glance, unfaced fiberglass insulation comes in at the lowest price per square foot. But taking a closer look at the thermal performance reveals the thermal performance of fiberglass at 3.5” thick is only a fraction of foam boards. In order to compare apples-to-apples, we need to compare the price of comparable R-values rather than comparing equal material thicknesses.

With polyiso nearly doubling the R-value of fiberglass, in order to match the R-21 of polyiso—fiberglass insulation would need to be installed at 5-½” thickness, coming in at around 0.85/SF for R-21 unfaced batts. Fiberglass insulation material costs are lower than polyiso, but that’s only part of the picture.

The other half of the equation is installation. Both foam board insulation and fiberglass are easy to install and can be done as a do-it-yourself project for small jobs. Professional installation costs are similar.

Meeting Code Requirements

Depending on your building’s location, you may be required by code to incorporate a specific R-value or even a set amount of continuous insulation around the building envelope. In these cases, polyiso insulation will give you the biggest bang for your buck with the highest R-value per inch—allowing you to insulate with less material. Plus, fiberglass cannot be used to provide continuous insulation since it requires framing for attachment and support. In some cases, both fiberglass and rigid foam insulation are used to achieve code requirements.

Choosing the Best Polyiso Insulation with Rmax

In the battle between foam board insulation vs fiberglass, builders must consider multiple factors to pick the right product for the job. If you’re leaning toward rigid insulation for your project, the insulation experts at Rmax can help you pick the right polyiso product for your application. Reach out to your local Rmax representative today to discuss your project needs.